Cobots: The New Frontier of Automation in the SME Sector 2023

Cobots: The New Frontier of Automation in the SME Sector 2023

Businesses today are searching for strategies to help them save costs and increase productivity in an era where the demand for qualified individuals in the nation is increasing dramatically.

The best approach for a small and medium-sized business (SME) to thrive is to emphasize stability and growth and always search for creative solutions to assist it. It is crucial to continue looking for ways to increase efficiency and cut expenses anywhere feasible to fortify your company’s defences against challenging economic conditions brought on by local, national, global, and even geopolitical issues.

Business owners in the SME category focus on increasing their efficiency and decreasing expenses within their operations since it is typically expensive because solid cash flow is vital to a company’s stability. The idea of automation via collaborating robots (cobots) is introduced.

The fundamental purpose of deploying cost-effective cobots is to unleash a company’s potential, regardless of size, enhancing production and efficiency. Businesses may expedite manual, time-sensitive operations when using cobots in a production line or warehouse, increasing their capabilities in constrained space and lead time.

Businesses today are searching for strategies to help them save costs and increase productivity in an era where the demand for qualified individuals in the nation is increasing dramatically. Hence, cobots have been widely adopted. These cobots have safety features, including power and force-limiting technology, that enable them to operate alongside humans. These IIoT-connected innovative technologies with sensor capabilities are more accurate, potent, and collaborative.

Furthermore, with increased rivalry and a change in customer needs, the manufacturing and industrial processes world is undergoing a profound transformation. Businesses use these innovative solutions because they provide a market advantage. Businesses are simultaneously maximizing their use of the few resources by looking at areas where automation might be helpful, thanks to cobots.

According to Fortune Business Insights, the worldwide cobot market is anticipated to increase at a CAGR of 42.7% from $1,358.2 million in 2021 to $16,387.3 million in 2028. Given the statistics, it is clear that cobots will be crucial to the growth of Industry 4.0, 5.0, and the Industrial Internet of Things (IIoT).

Because palletizing is one of the most labour-intensive occupations in a warehouse or industrial section, robotic palletizers are becoming more popular than their counterparts. In recent years, the quality of palletization has significantly improved because of automation and the usage of robotic palletizers.

This advanced technology has reduced the enormous stress these operations involve for workers. On the other hand, SMEs can cover a variety of palletizing solutions within their factory or warehouse thanks to the flexibility, simplicity, and convenience of programming and installation.

Due to these advantages, semi-automated and completely automated palletizing is widely used today. According to the most recent news on MarketWatch, these automatic palletizers are developing into more complex machinery that is capable of managing end-to-end palletizing and depalletizing possibilities.

Since the price might be categorized as an operational expense, these solutions can be considered an investment. Even better, these innovative approaches enable companies to take a more sustainable and energy-efficient course of action.

Integrating cobots into the legacy business model becomes more appealing when considering the value connected to these cobots—cost effectiveness, higher productivity, accuracy, shorter lead times, and sustainability. Therefore, you must use cobots or robotic palletizing for your SME, as you have everything to gain.

Collaborative robots, popularly known as “cobots,” represent a revolutionary advancement in automation technology that promises to transform the manufacturing landscape, particularly for small and medium-sized enterprises (SMEs).

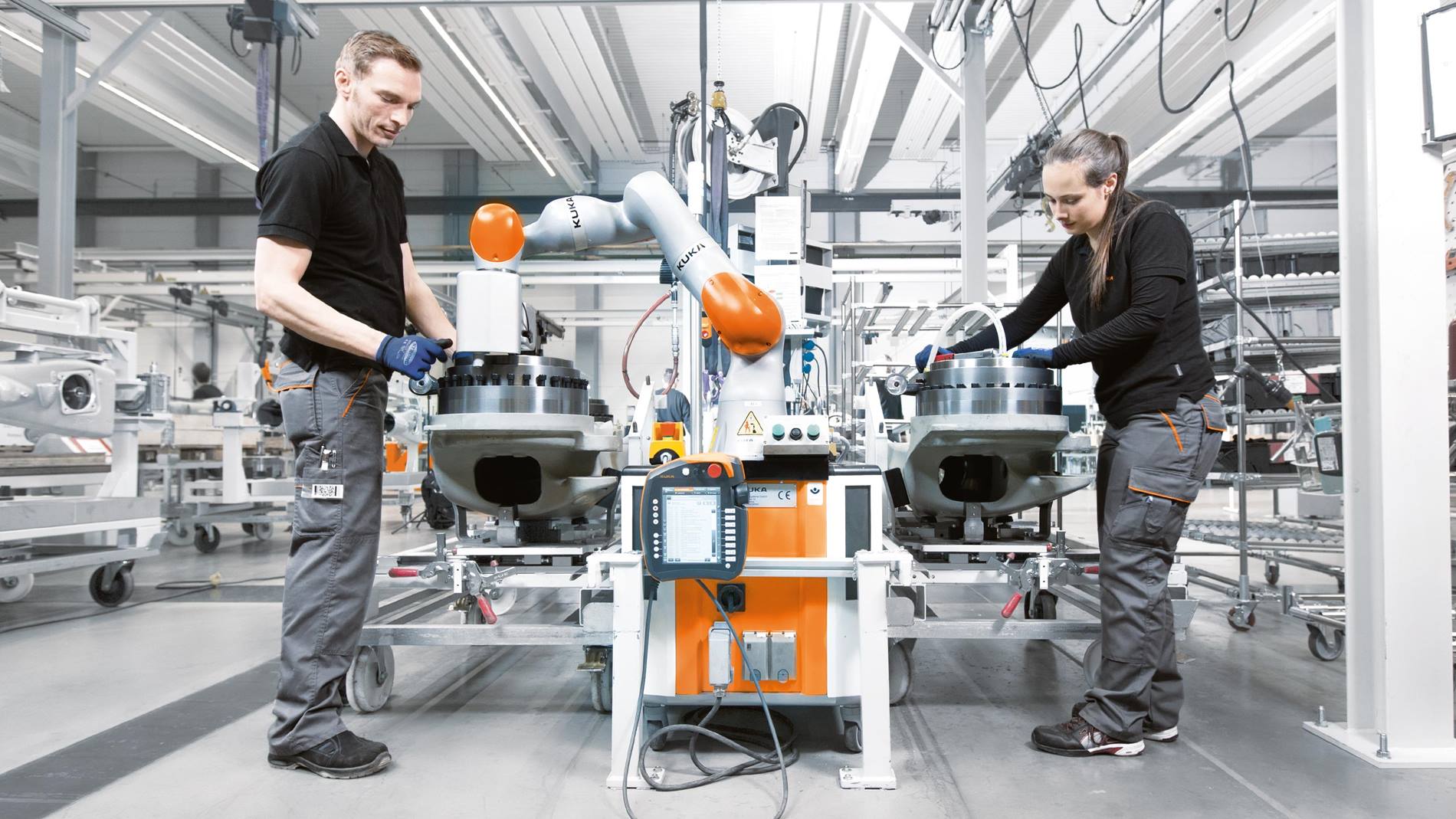

Unlike traditional robots, cobots are designed to work alongside human workers, assisting them in complex, repetitive, and tedious tasks. This coexistence creates a harmonious blend of human creativity and machine efficiency, offering SMEs a competitive edge in a rapidly evolving market landscape.

Collaborative robots are a subclass of industrial robots with built-in safety features to facilitate direct interaction with human workers. Cobots can range from small tabletop units to larger industrial systems. They usually come equipped with sensors, cameras, and machine-learning algorithms that allow them to understand and adapt to their environment.

Equipped with advanced sensors, cobots can detect human presence and operate safely in shared workspaces. Easy to program and reprogram for various tasks, making them suitable for the varied demands of SMEs.

Typically cheaper to install and maintain than traditional robots. They are designed for non-experts, allowing workers to program and operate them with minimal training.

Cobots can quickly take over repetitive tasks, freeing human workers to focus on more complex, value-added tasks. This increases productivity while reducing error rates and operational costs.

SMEs often face fluctuating demand and limited resources. Cobots can easily be reprogrammed for different tasks, allowing businesses to scale operations up or down without a massive overhaul.

Cobots are highly precise, which minimizes the risk of errors and enhances product quality. This precision is particularly useful for electronics, pharmaceuticals, and food processing sectors.

Cobots can handle dangerous tasks such as lifting heavy objects in sectors like manufacturing and logistics, reducing the risk of occupational injuries.

The relatively low initial investment and maintenance costs make cobots highly affordable for SMEs, who often operate on thin profit margins.

Cobots assist in assembly lines, material handling, and quality control. They are used in telemedicine, patient care, and even in assisting surgical procedures. They can manage inventory, assist in sorting, and help in customer service. They are employed in tasks like sorting produce, planting seeds, and monitoring crop health and are used in packaging, product sorting, and transportation.

Merging cobots into existing workflows may require time and adaptation. Compliance with safety and industry standards is essential. Staff may need training to operate and maintain cobots—ethical considerations around the potential for job loss due to automation.

Collaborative robots are:

- Game-changers for the SME sector.

- Offering a blend of efficiency.

Affordability that traditional industrial robots cannot match.

As technology evolves, cobots will likely become an even more integral part of SMEs, driving innovation and competitive advantage.

By understanding the capabilities and considerations associated with cobots, SMEs can make informed decisions that will shape their future success in an increasingly automated world.