Discoms’ Hindrance to Steel Sector’s Decarbonisation 2023

Discoms’ Hindrance to Steel Sector’s Decarbonisation 2023

The global steel industry is facing unprecedented pressure to decarbonize and reduce its environmental footprint. As one of the largest industrial sectors worldwide, steel production is a significant contributor to greenhouse gas emissions.

To combat climate change and meet ambitious sustainability goals, the steel sector has been exploring innovative technologies and strategies to transition towards low-carbon and eventually, carbon-free production.

However, the decarbonization of the steel sector is being hampered by the reluctance of Distribution Companies (Discoms) to embrace renewable energy sources and other sustainable practices.

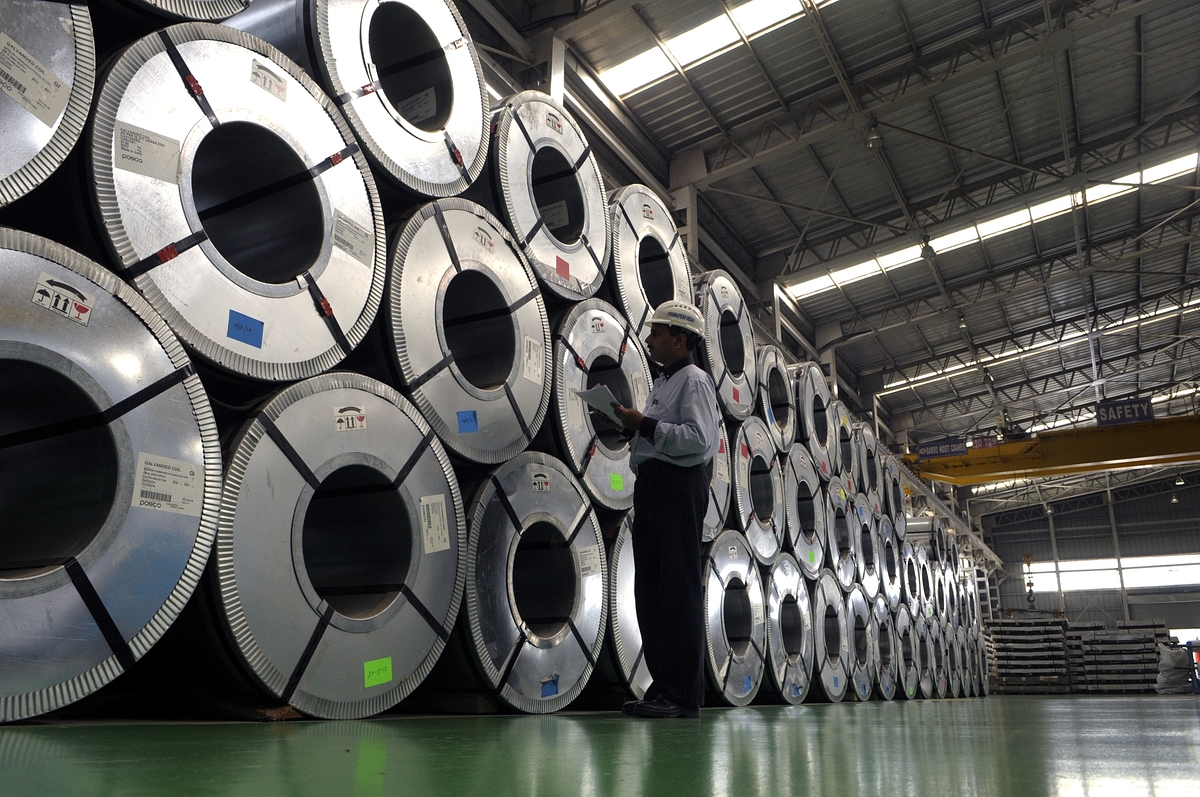

The steel industry is a vital component of the global economy, underpinning various sectors such as construction, automotive, infrastructure, and manufacturing.

However, its reliance on traditional production methods, primarily blast furnaces fueled by coal and coke, makes it a significant emitter of carbon dioxide (CO2).

According to the World Steel Association, the steel sector accounted for approximately 8% of global CO2 emissions in 2019. Recognizing the urgency of reducing emissions, steelmakers worldwide are actively pursuing decarbonization efforts.

Challenges in the Decarbonization of the Steel Sector

- High Energy Intensity: Steel production is inherently energy-intensive, making the sector reliant on a steady supply of electricity. Traditional methods, such as the basic oxygen furnace (BOF), require massive amounts of energy, primarily sourced from fossil fuels.

- Carbon-Intensive Inputs: The use of coal and coke in blast furnaces releases substantial carbon emissions. Even in modern electric arc furnaces (EAFs), electricity generated from fossil fuels can contribute significantly to emissions.

- Energy Price Fluctuations: Steel manufacturers are sensitive to energy price fluctuations. This vulnerability can be mitigated by transitioning to renewable energy sources with stable costs.

- Technological and Infrastructure Challenges: Transitioning to low-carbon or carbon-free steel production often requires substantial investments in new technologies and infrastructure, which may deter steel producers.

Distribution Companies (Discoms) play a pivotal role in the decarbonization journey of the steel industry. They are responsible for supplying electricity to steel manufacturers and other industrial sectors. Their willingness to embrace sustainable practices and renewable energy sources significantly impacts the ability of steel producers to decarbonize.

Discoms’ Reluctance to Embrace Renewable Energy:

- Dependency on Fossil Fuels: Many Discoms continue to rely on fossil fuels for electricity generation. They are slow to transition to cleaner energy sources, such as wind, solar, and hydropower.

- Lack of Infrastructure: The integration of renewable energy sources into the grid requires substantial investments in infrastructure and grid upgrades. Discoms may be hesitant due to cost concerns.

- Uncertain Regulatory Environment: In some regions, the regulatory environment does not favor the adoption of renewable energy sources. Discoms may face obstacles in obtaining regulatory approvals for renewable energy projects.

- Short-Term Profit Motive: Discoms often prioritize short-term profit over long-term sustainability. This can hinder their willingness to invest in renewable energy projects with longer payback periods.

To expedite the decarbonization of the steel sector and mitigate the impediments caused by Discoms’ reluctance, several key strategies should be considered:

- Regulatory Reforms: Governments should implement policies and regulations that incentivize Discoms to transition to renewable energy sources. This can include offering financial incentives, setting emission reduction targets, and creating a favorable policy environment for renewable energy projects.

- Grid Modernization: Discoms should invest in grid modernization to accommodate the intermittent nature of renewable energy sources. Smart grids and energy storage solutions can help ensure a stable energy supply to industrial consumers.

- Public-Private Partnerships: Collaboration between Discoms, steel manufacturers, and renewable energy providers can accelerate the adoption of clean energy. Public-private partnerships can share the costs and risks associated with transitioning to renewables.

- Education and Awareness: Raising awareness about the benefits of renewable energy and the importance of decarbonization can encourage Discoms to embrace sustainable practices.

The decarbonization of the steel sector is an essential step towards achieving global climate goals. While the industry is actively exploring innovative technologies and sustainable practices, the reluctance of Distribution Companies (Discoms) to embrace renewable energy sources and support decarbonization efforts remains a significant impediment.

To overcome this obstacle, regulatory reforms, grid modernization, public-private partnerships, and education are vital tools. Only through concerted efforts and a shared commitment to sustainability can Discoms and the steel industry work together to drive meaningful change and reduce the sector’s carbon footprint.